T he size and finish of these micro channels are critical and are used in many application

areas, such as microfluidic devices used in the medical industry, heat exchangers, fuel cells, batteries, bioengineering, aerospace, gas turbine blades, microelectronics and many other areas.

The unique nature of the Focus Variation principle, used in the InfiniteFocus systems, allows these micro features to be both imaged and measured in high resolution. As each data set contains several million data points it allows accurate measurement of these features which is not possible with single point probing via a CMM.

Focus Variation allows the quick and easy measurement without the

need for sophisticated holding devices or extensive program writing.

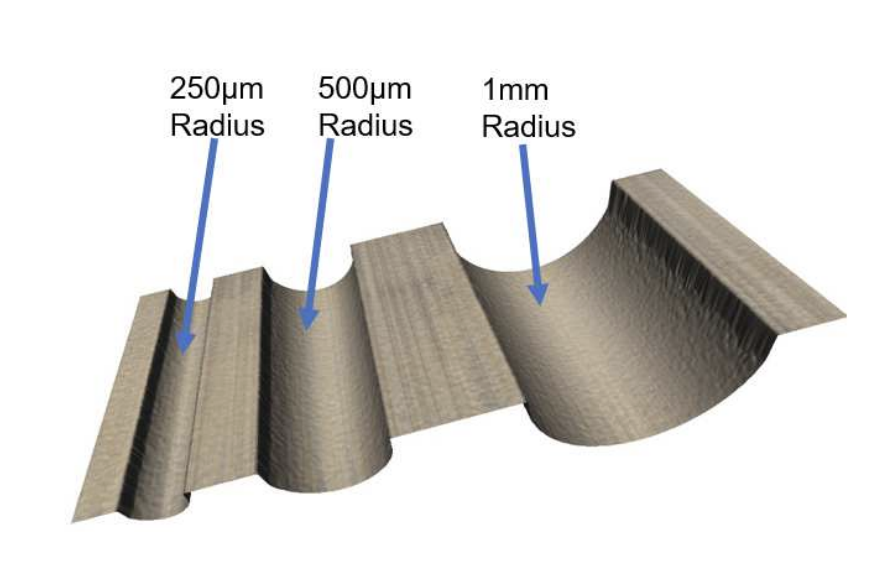

In this case the object to be measured is simply placed on the measurement table of the InfiniteFocus system, this allows X Y scanning up to 200 x 200 mm and a 3D model is produced as shown below.

Alternatively, the use of a cobot allows the measurement of several dedicated areas of the sample without any location limitations and orientation in space.

high density of the data that has been collected and it is on this data that measurements are made.

InfiniteFocus is a highly accurate and flexible optical 3D measurement system based on the Focus Variation technology. Using only one sensor, users verify dimensional accuracy surface finish of their components. By means of Vertical Focus Probing, an extension of Focus Variation vertical surfaces can be probed laterally. Components in high accuracy, with a high vertical resolution and in high repeatability. The robust measurement principle of Focus Variation in combination with a vibration-isolating hardware allows the systems to be used in a manufacturing environment.

With an automation interface, InfiniteFocus can also be used for fully automatic measurements in production.